Finding landmarks in the history of science is not difficult. What is challenging is identifying the discoveries that will eventually become the big chemical breakthroughs of the 21st century. Among the thousands of chemistry papers and patents that are published every day, which will contribute to a more sustainable future? In this context , the top 10 chemical inventions that are emerging solutions for the future are as follows:

Nanopesticides

The world population keeps growing. Some predictions suggest we will be almost 10 billion humans by 2050. Feeding that many people will require a huge increase in agricultural production while keeping crops sustainable: minimizing the environmental impact in terms of land use, reducing the amount of water needed, and mitigating the contamination by agrochemicals such as fertilizers or pesticides. Unsurprisingly, nanotechnology is attracting quite a lot of attention beyond the pharma and health industries. Tailored nano-delivery systems could also become a great tool for farmers, as it would eventually allow them to tackle the main problems of conventional pesticides such as environmental contamination, bioaccumulation, and the huge increase in pest resistance. There are very few publications that carefully analyze the benefits—and risks—of so-called “nanoagrochemicals” against their conventional alternatives. In most cases, the increase in efficacy is quite limited. However, in some cases, researchers have observed improvements by an order of magnitude under laboratory conditions. We still need a proper assessment of the efficacy of nano pesticides under field conditions. That is why some companies still investigate their potential, proving that there is still hope for this technology. Nanotechnology may not be the only ingredient to a successful new, more sustainable agriculture, but it will certainly lead to more sophisticated agrochemicals with a lower impact on the environment and human health.

Enantio selective organocatalysis

Chemists have always been inspired by nature. A few years back, researchers dreamt of a new kind of catalyst that, like most natural enzymes, would not require the use of expensive metals. “Organocatalysis” was born in the late 1990s and it has not stopped growing ever since. As chemists understood the industrial implications of lowering the catalyst amount, they crafted ways of creating chiral carbon-carbon bonds using just part per millions of organocatalysts. Many other fields have emerged from organocatalysis, and now industries have scaled-up asymmetric organocatalytic protocols to synthesize fine chemicals and drugs.

Solid-state batteries

Solid-state batteries were already envisioned in the 19th century but their development did not become a reality until recently. Compared to lithium-ion batteries that power our smartphones, tablets, and laptops, solid-state batteries are lighter, allow higher energy storage, and perform well at high temperatures. Moreover, unlike the electrolytes used in lithium-ion technology, solid-state electrolytes are not flammable, which could potentially avoid spontaneous fires and explosions. As for many other applications, polymers may be the best and most economical solution. There is still a lot of research to be done, especially because solid-state battery components are so closely bound together that it is quite complicated to understand how each of them behaves.

Academics and industrial researchers are closely working together to develop better non-destructive, operand technologies—electron microscopy and nuclear magnetic resonance & to understand how solid-state batteries perform. For most uses, the technology will still need a few more years.

Flow Chemistry

Chemistry is key in achieving some of the United Nation’s Sustainable Development Goals, a blueprint to attain a better and more sustainable future for all by the year 2030. Among them, flow chemistry, where reactions are run in a continuously flowing stream rather than in a batch, is particularly critical for tackling responsible consumption and production. Flow chemistry processes eventually minimize the risk of handling hazardous substances and increase productivity, both preventing harm and lowering the environmental impact. Although some people consider flow chemistry to be on a very early, small-scale laboratory stage, efficient industrial applications are increasingly common.

Reactive extrusion

Along with flow chemistry comes reactive extrusion, a technique that allows chemical reactions to happen completely solvent-free. The elimination of potentially toxic solvents makes this process environmentally friendly. It creates however many engineering challenges as it would require a complete redesign of the industrial processes that are now in place. Although extrusion processes have been widely-used and investigated by polymer and material experts, it is only now that other chemists are starting to dig into their possibilities in the preparation of organic compounds. Classic extrusion methods involve grinding reagents in a ball mill, but more advanced extrusion technologies using screws could even allow these solvent-free reactions to operate in flow setups. Once again, the downside lays on effectively adapting the systems and scaling them up. In their labs, chemists have used ball mills to prepare several attractive products—amino acids, hydrazones, nitrones, and peptides—and have achieved some very classic organic reactions—Suzuki coupling, click chemistry—but the examples in reactive extrusion conditions beyond polymers remain quite elusive. chemists have recently reported the formation of metal-organic frameworks and discrete metal complexes by screw extrusion, opening the door to new possibilities towards a cleaner and more sustainable solvent-free chemistry.

Porous material for Water Harvesting

According to the United Nations (UN), water scarcity affects more than 40 % of the global population and is projected to rise. On top of that, three in ten people lack access to safely-managed drinking water services. Chemistry could bring a solution to this problem identified as SDG 6“to change our world” using porous materials, particularly metal-organic frameworks (MOFs). Porous materials like MOFs have a sponge-like chemical structure with microscopic spaces that can selectively trap molecules, from gases—hydrogen, methane, carbon dioxide, water—to more complex substances, such as drugs and enzymes. Further research may of course explore all possibilities to find the best solution, not only for harvesting water, but also for purifying it, guaranteeing the achievement of one of the most important UN goals—achieving access to adequate and equitable sanitation and hygiene for all.

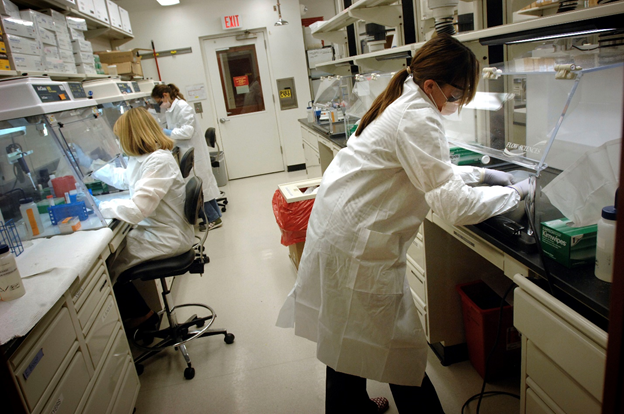

Directed evolution of selective enzymes

Directed evolution of enzymes and binding proteins is a manmade procedure built on molecular insights, which moves the evolution process into the laboratory and speeds it up. The procedure relies on the intended variation of protein sequences at a defined level of randomness. This is coupled with engineered screening and selection strategies. Directed evolution is an iterative procedure which involves the identification of a starting state protein, diversification of its gene, an expression and screening strategy, re-diversification, re-screening, and so on until a satisfactory performance level in terms of enzymatic activity, binding affinity or specificity is reached. Directed evolution of enzymes and binding proteins has become a widely used strategy in academic research as well as in the chemical and pharmaceutical industries. Directed evolution of enzymes tailors them to operate in new reaction conditions, optimizes their catalytic activity towards new substrates, and makes them catalyze new chemical reactions. Directed evolution of enzymes has widely expanded the repertoire of useful biocatalysts. The evolved enzymes offer efficient and environmentally-friendly alternatives to metals and organic catalysts in chemical and biotechnical industries.

From plastics to monomers

Some polymers, like polylactic acid (PLA), can be easily recycled into their monomers just by using heat. Others, such as polyethylene terephthalate (PET), can be similarly broken down into their most basic units. First, the polymer is treated with ethylene glycol, which breaks the long polymer chains down into oligomers. These smaller fragments melt at lower temperatures and therefore can be filtered to remove any impurities. Then, once the material has been purified, it’s completely broken down into the monomers, which are then purified again by distillation. Some bacteria have evolved such that they can also break down PET into pieces. Sometimes plastic is the only source of carbon around and you need to adapt if you want to survive. At least one species of Nocardia possesses an esterase that can break the ester bonds in PET and, more recently, Japanese researchers discovered Ideonellasakaiensis, a bacterium that can disintegrate a PET plastic film in about six weeks thanks to two different enzymes.

Reversible deactivation of radical polymerization

Reversible-deactivation of radical polymerizations (RDRP) was invented more than twenty years ago and revolutionized the world of polymers. These methods all rely on mechanisms that impose control over otherwise almost uncontrollable chain reactions, allowing us to design polymers with an accuracy that comes close to what nature is doing. chemists have also mastered polymerization processes that work in aqueous media, avoiding the use of volatile or hazardous solvents. The most recent advances allow them to obtain ultra-high-molecular-weight polymers in water in just a few minutes while keeping an exquisite control of the polymer branching. Some of these processes can work with a very low-energy light source, even just sunlight in some cases.

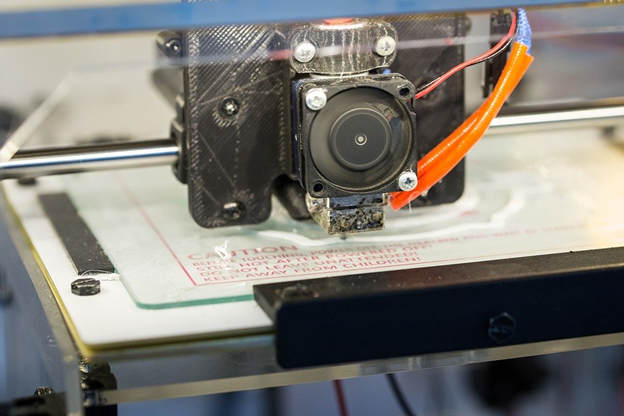

3D bioprinting

Bioprinting is one of today’s most promising technologies. Using 3D printers and inks made out of living cells and also biomaterials and growth factors, chemists and biologists have managed to fabricate artificial tissues and organs almost indistinguishable from their natural versions. 3D-bioprinting could revolutionize both diagnostics and treatments, as artificial tissues and organs could be easily used for drug screening and toxicology research. This technology could even lead to the creation of tissues and organs for ideal transplants that would not require a donor. Currently, scientists can already 3D-print tubular tissues (heart, urethra, blood vessels), viscous organs, and solid systems. Recently, Cambridge researchers even managed to 3D-print a retina, carefully depositing layers of different types of living cells to generate a construct that architecturally resembles the native eye tissue. Chemistry plays a central role in all the steps of this very complex process. First, organs and tissues need to be “scanned” to have a computational model. This is done using imaging techniques like computerized tomography (CT) scans and magnetic resonance imaging (MRI), both of which usually require chemical contrast agents such as gadolinium dyes. Then, bioprinting itself requires a myriad of chemicals to stabilize the bio-inks, trigger the assembly of the cells, or act as a scaffold for the printed tissue.

Chemistry, in the center of all the crossing disciplines behind the highly-complex 3D-bioprinting, will be key in the further development of this fringe technique that, according to some experts, could even build new organs that are better than the existing biological ones.

The goal is to promote and highlight the ubiquitous contributions of Chemistry in our daily lives, and to inspire the new generation of young scientists to fearlessly embrace the challenges we face, empowering them to find solutions through research, entrepreneurship, and creativity.